Adaptive Flaring Management System (AFMS): Optimizing Flare Gas Management and Enhancing Energy Recovery

Adaptive Flaring Management System (AFMS) emerges as a transformative solution. This advanced system leverages cutting-edge technologies to optimize flare gas management by predicting wind flow and dynamically adjusting the flare process to minimize emissions and maximize energy recovery. At Uniq Loop Technologies LLC, we have developed a state-of-the-art AFMS to help oil and gas operators reduce their environmental impact, ensure compliance with regulatory standards, and enhance energy efficiency.

The AFMS utilizes data from various sources, including wind speed and direction, temperature, pressure, and flow rates, to provide real-time insights into flare gas conditions. By adapting to changing environmental conditions, the AFMS ensures that excess gas is flared in a controlled manner, minimizing harmful emissions and optimizing energy recovery. The system not only improves operational efficiency but also helps meet stringent environmental regulations by ensuring compliance with emission standards.

Applications of the Adaptive Flaring Management System (AFMS):

1. Wind Flow Prediction and Optimization

AFMS uses advanced predictive algorithms to forecast wind flow patterns around flare stacks. By predicting wind direction and speed, the system can adjust the flare process in real time, ensuring that emissions are directed away from sensitive areas. This reduces the impact of emissions on local communities and the environment.

2. Emission Reduction

One of the key goals of AFMS is to reduce harmful emissions from flaring activities. The system optimizes the burning process to ensure that excess gas is flared in a controlled and efficient manner, minimizing the release of CO2, methane, and other greenhouse gases into the atmosphere. This not only benefits the environment but also helps companies meet regulatory emission reduction targets.

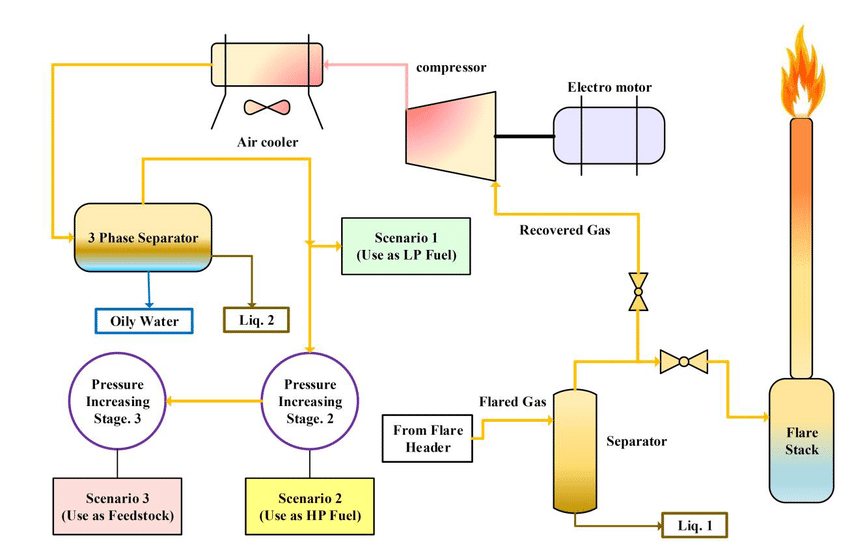

3. Energy Recovery

Flare gas is typically wasted during normal operations, but AFMS helps optimize energy recovery from flaring activities. By ensuring that excess gas is burned efficiently, AFMS allows energy to be recovered and utilized for other operational processes. This improves overall energy efficiency and reduces the need for additional energy sources.

4. Regulatory Compliance

The oil and gas industry is subject to strict environmental regulations, including limits on emissions from flaring activities. AFMS ensures that flare gas management complies with local and international regulations by continuously monitoring flare gas conditions and emissions levels. This reduces the risk of fines and penalties associated with non-compliance.

5. Real-Time Monitoring and Reporting

The AFMS provides operators with real-time data on flare gas conditions, including temperature, pressure, and flow rate. This data can be used to generate reports and dashboards that provide insights into flare gas management performance. Operators can use this information to make informed decisions and adjust operations as needed.

Advantages of the Adaptive Flaring Management System

The Adaptive Flaring Management System offers several advantages that improve both operational efficiency and environmental sustainability:

1. Optimized Gas Utilization

By predicting wind flow and adjusting flare operations accordingly, AFMS ensures that flare gas is burned efficiently. This reduces the waste of valuable energy and enhances the overall energy utilization of the facility.

2. Reduced Environmental Impact

One of the biggest benefits of AFMS is its ability to minimize harmful emissions. By optimizing the flaring process, the system reduces the release of CO2, methane, and other pollutants into the atmosphere. This helps operators comply with environmental regulations and contributes to global efforts to reduce greenhouse gas emissions.

3. Increased Energy Recovery

AFMS improves energy recovery by ensuring that excess gas is burned in the most efficient way possible. This reduces the need for additional energy sources and helps facilities operate more sustainably. Energy recovery can be used for other operational processes or returned to the grid.

4. Cost Savings

By reducing emissions, optimizing flare operations, and recovering energy, AFMS helps companies save on energy costs and avoid penalties associated with non-compliance. The system also reduces operational downtime by providing real-time data and alerts that allow operators to proactively address issues before they become critical.

5. Enhanced Safety

AFMS enhances safety by ensuring that flare operations are optimized and emissions are directed away from sensitive areas. The system continuously monitors flare conditions, ensuring that flare stacks are operating safely and reducing the risk of accidents or environmental incidents.

Value Added by the Adaptive Flaring Management System (AFMS)

1. Reduction in Flaring Emissions

Reducing flare gas emissions can help companies avoid environmental fines, which can range from AED 500,000 to AED 2 million annually for non-compliance. By optimizing flare gas management and ensuring compliance, AFMS can help save up to AED 1 million per year in fines and penalties.

2. Energy Recovery and Cost Savings

Flare gas that is efficiently burned and recovered can be redirected to energy production. With the AFMS, companies can recover up to 15% to 20% more energy from flare gas. This translates into energy savings of up to AED 3 million per year depending on the size and scale of the operation.

3. Optimized Gas Utilization

By optimizing the burning process, AFMS can reduce the amount of gas flared, resulting in energy cost savings. This can lead to a reduction in operational costs by up to AED 500,000 annually.

4. Improved Operational Efficiency

By reducing downtime and optimizing flare operations, AFMS enhances operational efficiency, leading to savings of AED 200,000 to AED 500,000 per year.