Complete A to Z Software for Manufacturing Units

Complete A to Z Software for Manufacturing Units: Revolutionizing Operations with Uniq Loop Technologies LLC

Introduction

In today’s fast-paced manufacturing environment, achieving seamless operations is essential for companies striving for efficiency, cost reduction, and enhanced quality. The increasing complexity of global supply chains, customer demands for shorter lead times, and the need to maintain high standards of product quality have prompted manufacturers to look for innovative solutions. One such solution is the complete end-to-end software that integrates production planning, quality control, inventory management, and predictive maintenance—ultimately optimizing overall operations.

At Uniq Loop Technologies LLC, we specialize in providing a Complete A to Z Software for Manufacturing Units, an integrated system designed to streamline and automate the entire manufacturing process. Our software solution addresses the core challenges faced by modern manufacturers, ensuring optimized production, reducing downtime, and improving decision-making through real-time data and predictive analytics.

This blog explores how Uniq Loop’s comprehensive manufacturing software solution works, which industries can benefit from it, and the many advantages it provides. We will also explore the value it adds to manufacturing operations in the UAE by comparing it with the current practices employed in the region.

What is Complete A to Z Software for Manufacturing Units?

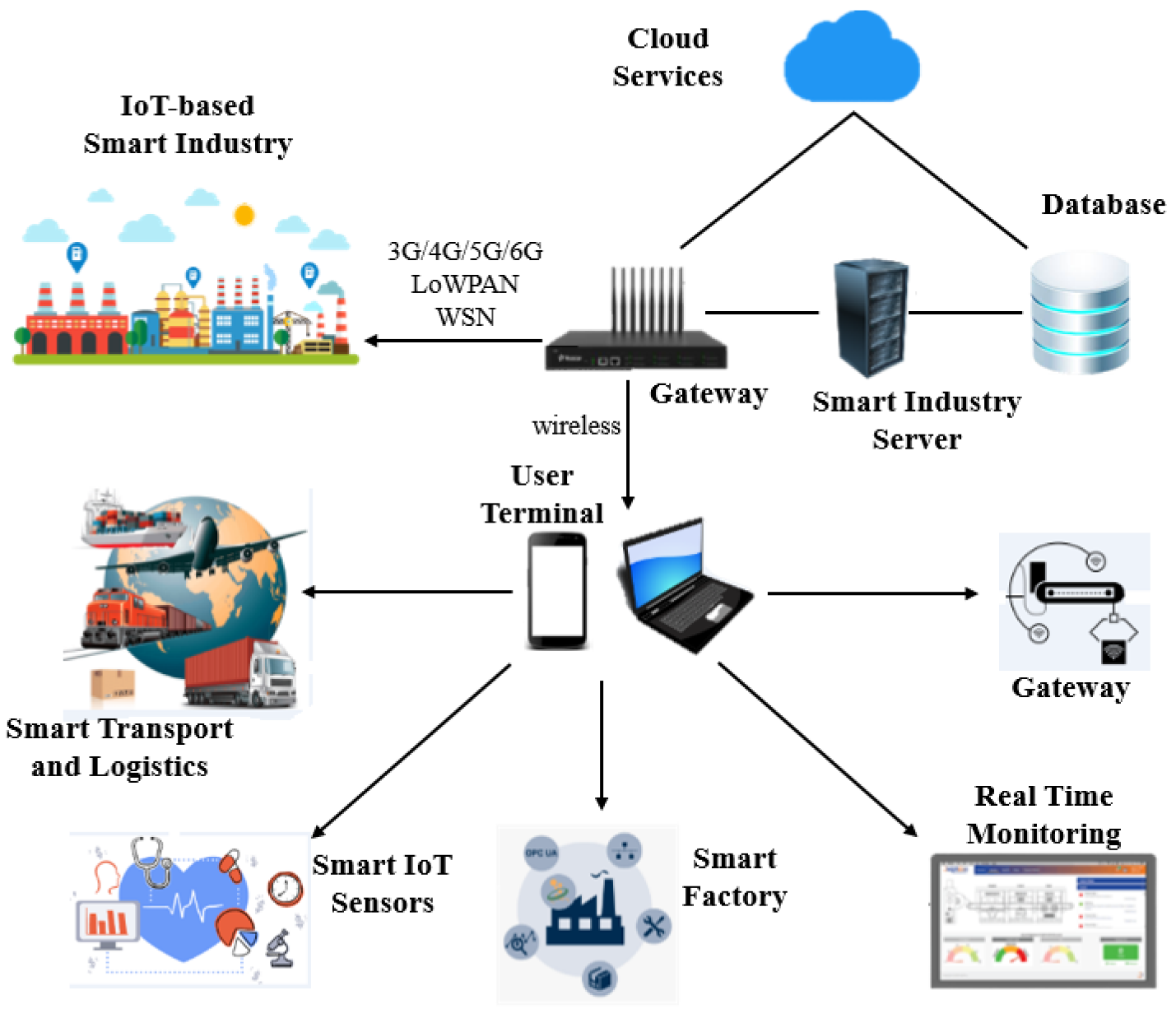

The Complete A to Z Software is an integrated solution designed to manage every aspect of a manufacturing unit’s operations. It connects all the key areas of the manufacturing process, such as production planning, inventory management, quality control, and predictive maintenance, into one unified platform.

Instead of relying on separate, isolated systems for each function, our software streamlines operations and ensures that all departments and processes communicate with each other in real-time. This leads to better data visibility, faster decision-making, and more efficient use of resources.

Here’s a breakdown of the major components of the software:

1. Production Planning

Production planning is a critical aspect of manufacturing operations. The software ensures that all resources, including raw materials, machinery, and labor, are efficiently scheduled and utilized. This planning function minimizes bottlenecks and ensures that production targets are met on time, within budget, and without unnecessary delays.

2. Quality Control

Maintaining high-quality standards is essential in manufacturing. The software monitors quality at every stage of production, ensuring that defects are caught early, and products meet regulatory and customer specifications. This minimizes wastage and rework while ensuring customer satisfaction.

3. Inventory Management

Effective inventory management is crucial to avoid both stockouts and overstocking. The software offers real-time tracking of raw materials, semi-finished goods, and finished products. It also facilitates automated reordering, ensuring that inventory levels are optimized based on demand forecasts and production schedules.

4. Predictive Maintenance

Predictive maintenance uses advanced analytics to monitor the health of machines and equipment in real-time. The software detects anomalies or potential failures before they cause downtime, allowing manufacturers to perform maintenance only when necessary and avoiding unnecessary costs associated with unplanned downtime.

Industries That Can Benefit from Complete A to Z Software

The Complete A to Z Software for Manufacturing Units is a versatile tool that can be applied across various industries. Here are some of the key sectors that can significantly benefit from an integrated software solution:

1. Automotive Manufacturing

In the automotive sector, maintaining precise production schedules and ensuring the quality of thousands of components is crucial. Our software allows manufacturers to streamline production planning, monitor parts inventory, and ensure that each component is manufactured to meet strict industry standards.

2. Electronics and Electrical Equipment

Manufacturers of electronics and electrical goods face challenges related to product quality, inventory management, and supply chain complexity. By integrating all operational aspects through our software, manufacturers can track the lifecycle of each product from raw material procurement to final assembly.

3. Food and Beverage Manufacturing

In food and beverage manufacturing, quality control, traceability, and regulatory compliance are paramount. The software ensures that the production process is optimized, inventory levels are accurately tracked, and products are produced in compliance with safety regulations.

4. Pharmaceutical Manufacturing

Pharmaceutical manufacturers require rigorous quality control processes and compliance with regulatory standards. Our software integrates production scheduling with quality control checks, inventory tracking, and maintenance to ensure a continuous, compliant, and efficient production line.

5. Consumer Goods Manufacturing

Manufacturers of consumer goods must balance cost-efficiency with product quality. The integrated software optimizes production scheduling, ensures quality at every stage, and provides detailed insights into inventory management, helping reduce waste and improve delivery timelines.

Applications of Complete A to Z Software for Manufacturing Units

The software’s applications are vast and cover every aspect of manufacturing operations, from the initial planning phase to final product delivery. Below are the key applications of the software:

1. Production Planning and Scheduling

By automating production planning, the software ensures that manufacturing resources, such as labor, materials, and machines, are utilized efficiently. It helps manufacturers plan production cycles based on demand, reducing overproduction and stockpiling. It also provides real-time adjustments for any disruptions, such as machine breakdowns or supply shortages.

2. Real-Time Monitoring and Tracking

The software provides real-time insights into the production process, machine status, worker performance, and inventory levels. Managers can monitor operations remotely, ensuring that processes are running smoothly and that any issues are addressed immediately.

3. Quality Control and Traceability

The software performs continuous quality checks at various stages of production. It logs product specifications, defects, and other quality-related issues, ensuring traceability. This ensures that defective products are caught early in the production process, minimizing waste and ensuring customer satisfaction.

4. Inventory Management and Optimization

With real-time tracking of raw materials and finished goods, the software helps manufacturers avoid stockouts and minimize excess inventory. It automatically generates reorders when stock levels fall below preset thresholds, ensuring a smooth flow of materials and reducing the risk of production delays.

5. Predictive Maintenance

Predictive maintenance is a game-changer for manufacturing units. The software uses sensor data and machine learning algorithms to monitor equipment conditions and predict failures before they occur. This reduces the need for costly emergency repairs and downtime, resulting in better machine utilization.

6. Data-Driven Decision Making

By aggregating data from all aspects of production, inventory, quality, and maintenance, the software enables manufacturers to make informed, data-driven decisions. These decisions can optimize production schedules, improve resource allocation, and identify bottlenecks that impact operational efficiency.

Advantages and Benefits of Complete A to Z Software

The Complete A to Z Software for Manufacturing Units offers a range of advantages that contribute to more efficient, cost-effective, and high-quality operations. Below are the key benefits:

1. Increased Efficiency and Reduced Downtime

By automating various manufacturing processes and providing real-time insights into operations, the software enables manufacturers to improve efficiency and reduce downtime. Predictive maintenance further ensures that equipment is maintained proactively, avoiding costly unplanned downtime.

2. Enhanced Quality and Compliance

The software’s quality control features ensure that every product meets predefined standards, reducing the risk of defective products reaching the market. Real-time tracking ensures compliance with industry regulations and quality certifications, such as ISO standards.

3. Cost Savings

By optimizing production planning, inventory management, and maintenance, the software helps manufacturers reduce waste and operating costs. A decrease in downtime, fewer quality control issues, and better use of inventory result in significant cost savings.

4. Streamlined Operations and Transparency

An integrated system connects all departments, providing transparency and streamlining processes across the board. Managers can quickly identify inefficiencies or bottlenecks in the production cycle and take corrective actions before they become bigger issues.

5. Better Resource Utilization

The software ensures that resources, such as labor, materials, and machinery, are allocated efficiently. This prevents overstaffing, underutilization of machines, and excessive inventory, all of which lead to higher operating costs.

Quantifying the Value Added by Uniq Loop’s Manufacturing Software

In the UAE, manufacturing companies often rely on traditional methods, such as paper-based tracking, manual scheduling, and decentralized systems for managing quality control and inventory. These methods can be time-consuming, prone to human error, and inefficient in terms of resource utilization.

By implementing Uniq Loop’s Complete A to Z Software, manufacturers can realize substantial financial benefits. Let’s look at a few key areas where value is added:

1. Reduction in Downtime and Maintenance Costs

Currently, many manufacturing units in the UAE face significant downtime due to unplanned equipment failures. With predictive maintenance capabilities, manufacturers can reduce downtime by up to 30%. For a company that loses AED 1,000,000 annually due to downtime, this could translate into savings of AED 300,000 per year.

2. Improved Inventory Management and Cost Reduction

Inefficient inventory management often leads to stockouts or excess stock, resulting in lost sales or unnecessary warehousing costs. By optimizing inventory levels, companies can reduce inventory holding costs by 20%. For a company with annual inventory costs of AED 2,000,000, this could mean saving AED 400,000 annually.

3. Enhanced Quality Control and Reduced Rework

The quality control features of the software ensure that defects are detected early in the production cycle, reducing rework and scrap. If a company spends AED 500,000 annually on rework, the software could reduce this cost by 40%, saving AED 200,000 each year.

4. Streamlined Production and Increased Throughput

The software’s production planning and scheduling capabilities allow manufacturers to streamline their operations, resulting in improved throughput. A company that produces 100,000 units annually could increase production efficiency by 10%, resulting in 10,000 additional units without increasing labor or machinery costs.

Conclusion

The Complete A to Z Software for Manufacturing Units by Uniq Loop Technologies LLC offers a comprehensive solution for modern manufacturing challenges. By integrating production planning, quality control, inventory management, and predictive maintenance, the software optimizes operations, reduces downtime, and enhances quality across the board.

For manufacturers in the UAE, implementing this software can lead to significant cost savings, improved efficiency, and better resource utilization, providing a substantial return on investment. As the manufacturing industry continues to evolve, those who embrace integrated software solutions will be better equipped to stay competitive and meet the demands of the market.