Work Order System

Work Order System: Revolutionizing Job Assignments and Resource Utilization for Efficient Maintenance Operations

Introduction

The efficiency of maintenance and service operations is critical for businesses across various industries, especially when dealing with multiple job assignments, subcontractors, and resource management. Traditionally, work order management has been a complex, time-consuming process prone to human errors, delays, and miscommunication. However, with the advent of advanced technology, the Work Order System from Uniq Loop Technologies LLC is transforming the way businesses manage and automate work assignments, ensuring real-time tracking, error-free processes, and optimal resource utilization.

This automated solution is a game-changer, especially for companies in industries like construction, oil and gas, manufacturing, utilities, and healthcare, where seamless coordination, speed, and accuracy are essential. In this blog, we will explore how Uniq Loop’s Work Order System works, the industries it benefits, its applications, and the significant advantages it provides, focusing particularly on its value-added impact and quantified money-saving potential by comparing it with current practices in the UAE.

Industries That Can Benefit from a Work Order System

Several industries can significantly benefit from automating their work order processes. Let’s explore some of them in detail:

1. Facility Management

In facilities management, maintenance requests, job assignments, and contractor coordination need to be streamlined for operational efficiency. Uniq Loop’s Work Order System automates work order creation, progress tracking, and subcontractor approvals, allowing facility managers to monitor maintenance tasks, service requests, and resource allocation more efficiently.

2. Construction & Engineering

Construction sites require effective coordination of labor and resources. Managing subcontractors, ensuring timely approvals, and tracking work progress is complex, but with Uniq Loop’s system, the construction process becomes more efficient, with real-time updates, reducing the risk of delays.

3. Manufacturing & Industrial Plants

Manufacturing plants depend heavily on machinery and equipment, and downtime is costly. A Work Order System streamlines maintenance scheduling, ensures timely interventions, and tracks progress to avoid equipment failure. This enhances productivity and minimizes unplanned downtime.

4. Oil & Gas

In the oil and gas sector, maintenance is critical for ensuring the safety and operational efficiency of equipment. The Work Order System enables real-time work tracking, from job creation to completion, improving the maintenance and repair workflow and enhancing safety in this high-risk industry.

5. Utilities & Infrastructure

Utilities such as electricity, water, and gas providers need efficient systems for handling maintenance and repair requests. Uniq Loop’s system ensures that critical issues are addressed promptly, with resources and time tracked effectively to minimize service disruption.

6. Healthcare

Hospitals and healthcare facilities need to ensure that all equipment is regularly maintained and in optimal working condition. Uniq Loop’s system helps automate equipment maintenance requests, track service tasks, and streamline approval processes, ensuring healthcare staff can focus on patient care while operational tasks are handled seamlessly.

Application of Uniq Loop’s Work Order System

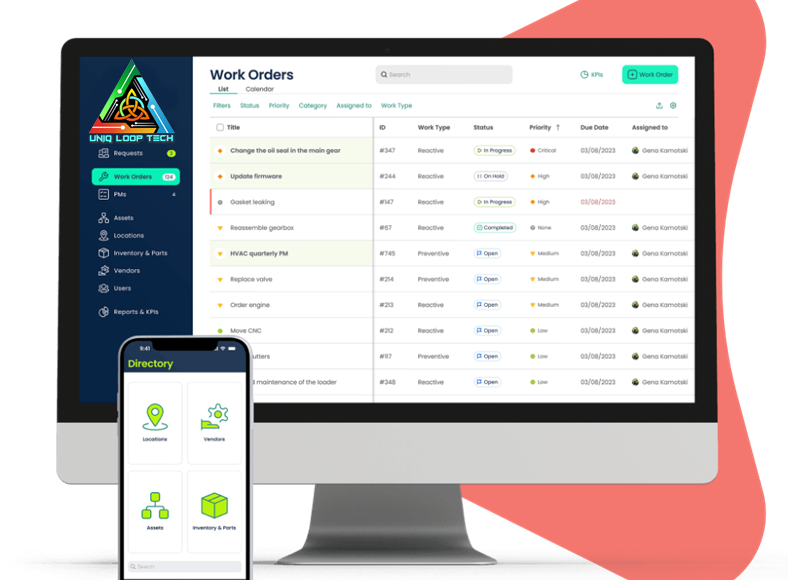

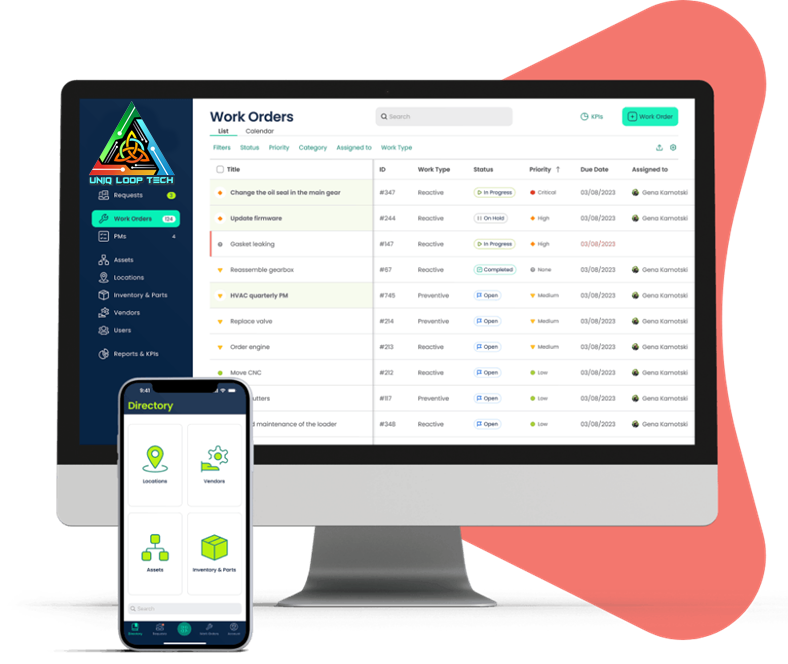

Uniq Loop’s Work Order System offers an end-to-end solution for managing the entire lifecycle of work orders. Here are some key features of the system:

1. Job Assignment & Scheduling

The system automates the creation and assignment of work orders, scheduling them based on priority and the availability of resources (such as technicians, tools, and materials). It enables quick job allocation and ensures that no resources are underutilized or overburdened.

2. Fill, Check, Review & Approve Process

Uniq Loop’s system digitizes and automates the work order process from start to finish. The work order is created, filled, checked, reviewed, and approved automatically, eliminating bottlenecks and reducing manual interventions. This process ensures that each step in the job cycle is tracked and logged.

3. Subcontractor Management

The system allows businesses to assign jobs to subcontractors and track their progress in real-time. It offers a clear view of subcontractor performance, ensuring transparency and accountability. Notifications are sent for updates and approvals, ensuring timely service delivery.

4. Resource Utilization Tracking

One of the most important features of the Work Order System is its ability to track resource utilization. This feature ensures that resources, such as manpower, tools, and equipment, are used efficiently and are allocated based on priority and availability. The system helps prevent waste and optimize resource allocation.

5. Automated Notifications & Alerts

The system sends automated notifications to all relevant parties regarding job status, approvals, progress, and completion. This helps maintain smooth communication between management, maintenance teams, and subcontractors, ensuring everyone is aware of task updates.

6. Integration with Other Systems

Uniq Loop’s Work Order System integrates with asset management, inventory, and other enterprise systems to provide a holistic view of operations. This integration ensures that maintenance schedules align with asset lifecycles, and inventory levels are optimized.

7. Mobile Access

Uniq Loop’s system is accessible via mobile devices, allowing field technicians to update job statuses, report issues, and request approvals directly from the job site. This mobile functionality enhances real-time data capture and communication.

Advantages of Uniq Loop’s Work Order System

1. Streamlined Workflow

By automating the work order process, Uniq Loop’s system eliminates bottlenecks, delays, and manual errors. Each step of the process, from job assignment to completion, is optimized for speed and accuracy.

2. Enhanced Resource Utilization

Optimized scheduling ensures that the right resources are available at the right time. This leads to better resource utilization, reducing idle times and avoiding over-allocation.

3. Real-Time Tracking

Uniq Loop’s Work Order System offers real-time tracking of job progress, which improves transparency. Managers can see the status of each work order, track performance, and make quick adjustments if needed.

4. Reduced Operational Costs

Automating work orders helps reduce operational costs by minimizing manual labor, reducing errors, and preventing unnecessary delays. This leads to lower overheads and better financial control.

5. Improved Communication

Automated notifications and alerts keep all stakeholders informed and aligned, improving communication across teams and subcontractors. This ensures that no task is missed and every work order is addressed promptly.

Benefits of Implementing Uniq Loop’s Work Order System

1. Increased Productivity

Automating work orders accelerates job completion, reducing the time spent on administrative tasks. The productivity of maintenance teams improves as they can focus more on actual work rather than paperwork.

2. Lower Operational Costs

Eliminating inefficiencies in the work order process leads to cost savings. By optimizing resource allocation and reducing delays, the company can achieve significant cost reductions in operations.

3. Faster Turnaround Times

With automated scheduling and approval processes, work orders are completed faster, leading to quicker resolution of issues, reduced downtime, and improved service delivery.

4. Improved Decision-Making

Uniq Loop’s system offers valuable data insights that help managers make better, data-driven decisions regarding resource allocation, job prioritization, and operational improvements.

5. Better Customer Satisfaction

With streamlined processes and faster service delivery, customers experience fewer disruptions, better quality service, and increased satisfaction. Timely job completion results in improved client relationships.

Impact and Value Added in the UAE

Current Practices in the UAE

Currently, many businesses in the UAE still rely on manual or semi-automated work order systems, which often lead to delays, miscommunication, and inefficiencies. Without automation, businesses experience longer response times, missed work orders, and increased resource wastage.

Quantifiable Value Added with Uniq Loop’s Work Order System

30% Reduction in Work Order Processing Time

– By automating job assignments and approvals, businesses can significantly cut down the time spent on processing work orders.

25% Improvement in Resource Utilization

– Optimized scheduling and resource allocation can improve overall resource efficiency, ensuring no resources are left idle.

20% Cost Savings in Maintenance Operations

– With faster job completions and reduced operational inefficiencies, companies can cut down on maintenance costs.

40% Reduction in Work Order Errors

– Automated workflows reduce the risk of human error, ensuring work orders are completed accurately.

50% Faster Response Time

– Automated notifications ensure quicker actions for urgent jobs, reducing downtime and operational disruptions.

Financial Impact

Manufacturing Sector

: With automated work orders,

companies can save up to AED 1.5 million annually

by reducing equipment downtime and improving maintenance scheduling.

Construction Sector

: Automating subcontractor coordination can lead to savings of

AED 1.2 million annually

, improving project timelines and resource utilization.

Oil & Gas

: Optimizing field service work can reduce maintenance costs by

AED 2 million annually

, improving asset management and extending equipment lifespan.

Healthcare

: By automating maintenance schedules, hospitals and healthcare providers can save up to

AED 600,000 annually

, reducing equipment failures and ensuring uninterrupted service.

Conclusion

Uniq Loop’s Work Order System provides an innovative solution to automate job assignments, track progress, and ensure efficient resource utilization. It streamlines the entire work order lifecycle, reducing inefficiencies, minimizing downtime, and ultimately driving cost savings. By adopting this system, businesses in the UAE can experience significant improvements in productivity, decision-making, and overall operations.

In comparison to current practices, the financial benefits of implementing Uniq Loop’s Work Order System are clear: businesses can reduce operational costs, improve resource utilization, and enhance customer satisfaction, all while saving millions of AED annually. Whether you’re in construction, manufacturing, oil & gas, or healthcare, Uniq Loop’s Work Order System is the key to optimizing your maintenance and service operations.

Contact Uniq Loop Technologies LLC today to learn more about how we can help you automate your work orders and improve your operational efficiency.