Predictive Maintenance Software

Predictive Maintenance Software: Revolutionizing Equipment Management and Saving Costs in UAE Industries

Introduction

In today’s competitive and fast-paced business environment, companies across various industries are increasingly reliant on machinery and equipment for their operations. While these assets play a crucial role in productivity, they also come with their share of challenges, particularly when it comes to maintenance. Unplanned equipment failures can lead to costly repairs, production delays, and significant downtime, resulting in lost revenue and disrupted workflows.

Enter Predictive Maintenance Software — an advanced solution that helps prevent unexpected equipment failures by analyzing real-time data and accurately forecasting maintenance needs. This technology is transforming how industries manage their assets, improving operational efficiency and saving valuable time and resources.

At Uniq Loop Technologies LLC, we offer predictive maintenance solutions that empower businesses to optimize their asset management strategies. Our software leverages artificial intelligence (AI) and machine learning (ML) algorithms to predict when and where maintenance should be performed, eliminating the need for time-based maintenance schedules and reducing the risk of unscheduled downtime. By predicting issues before they occur, companies can maintain continuous operations while maximizing the lifespan of their machinery.

In this blog, we’ll explore the role of predictive maintenance software, the industries that can benefit from it, its applications, advantages, and the substantial impact it can have on a company’s bottom line, particularly in the UAE.

What is Predictive Maintenance Software?

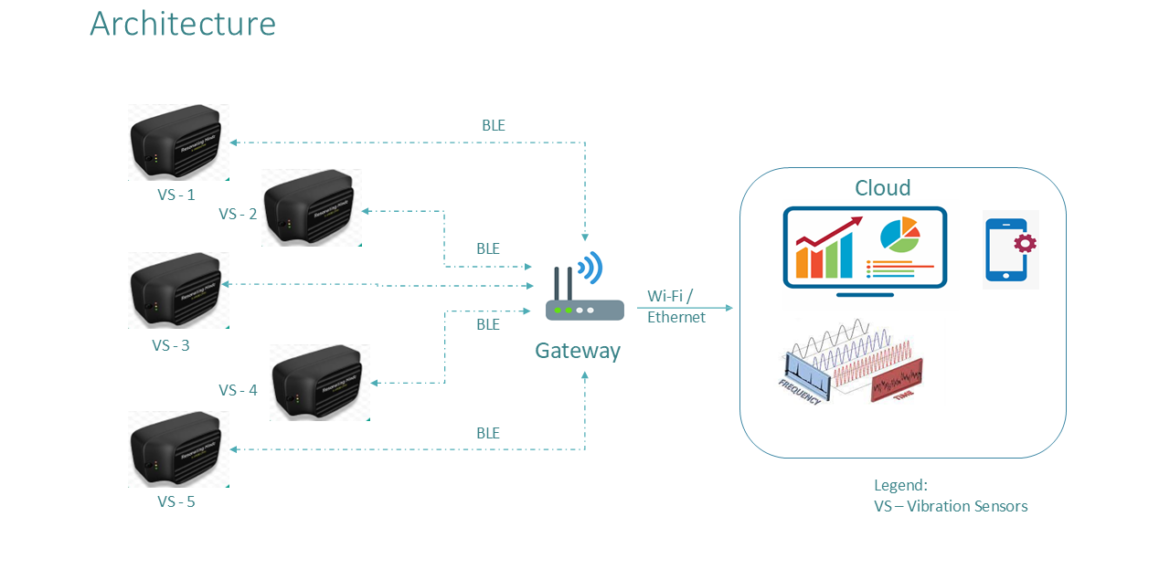

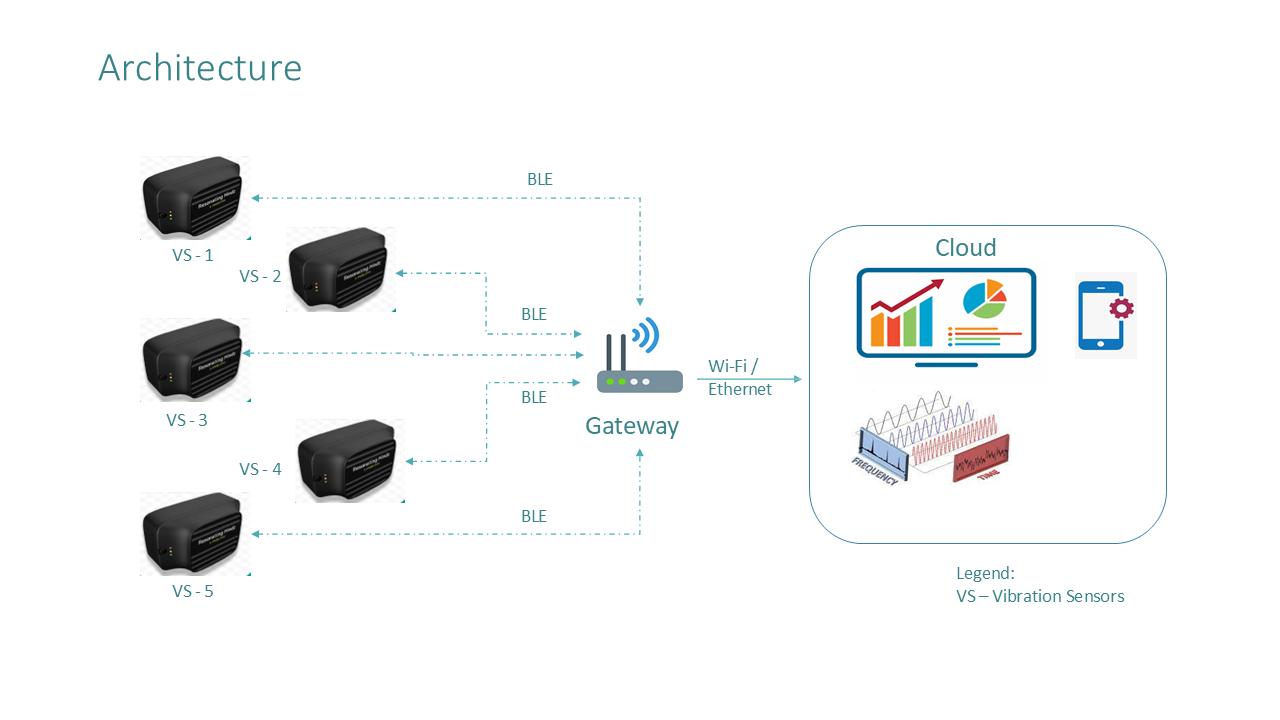

Predictive maintenance (PdM) is a proactive approach to equipment management that relies on data-driven insights to forecast when a piece of equipment is likely to fail. By utilizing sensors and IoT devices that collect real-time data from machinery, predictive maintenance software can analyze factors like temperature, pressure, vibration, and humidity. Machine learning algorithms then process this data to identify patterns and anomalies, predicting when a part is likely to wear out or malfunction.

The key difference between predictive maintenance and traditional maintenance practices, such as reactive or preventive maintenance, lies in its ability to predict failures before they happen, rather than relying on fixed schedules or waiting for equipment to fail.

Industries That Can Benefit from Predictive Maintenance Software

Predictive maintenance software is particularly beneficial for industries that rely on high-value, complex equipment that runs continuously or in critical operations. Here are the industries that can greatly benefit from implementing predictive maintenance:

1. Manufacturing

Manufacturing facilities, especially those with heavy machinery, experience significant downtime due to unexpected equipment failures. Predictive maintenance can help manufacturers track their machinery’s health, reduce maintenance costs, and avoid production delays.

2. Oil & Gas

The oil and gas industry deals with harsh environments and high-risk operations. Equipment failure in this sector can result in costly downtime, safety hazards, and severe environmental consequences. Predictive maintenance can help monitor pumps, compressors, pipelines, and other equipment, preventing failures and improving safety.

3. Transportation and Logistics

Transportation fleets, warehouses, and logistics companies rely heavily on vehicles and equipment for smooth operations. Predictive maintenance can ensure that vehicles, cranes, conveyors, and other machinery are running at their best, reducing breakdowns and costly repairs.

4. Power Generation

Power plants require constant equipment operation, as any failure in turbines, generators, or other critical infrastructure can lead to power outages and production disruptions. By employing predictive maintenance software, power companies can ensure their assets are running efficiently, preventing costly downtime and safety risks.

5. Aerospace and Aviation

Aviation is one of the most high-stakes industries, where equipment reliability is essential to safety. Predictive maintenance software can help ensure aircraft components such as engines, landing gear, and avionics are maintained at optimal performance levels, minimizing the risk of mechanical failure.

6. Construction

Construction companies use heavy machinery like cranes, bulldozers, and excavators, which are essential for completing projects on time. By using predictive maintenance software, these companies can optimize the maintenance of their machinery, avoid costly breakdowns, and ensure project timelines are met.

Applications of Predictive Maintenance Software

The applications of predictive maintenance software span across a variety of operations. Below are some key areas where predictive maintenance is highly effective:

1. Real-time Monitoring and Data Collection

Predictive maintenance software integrates with sensors and IoT devices to collect real-time data from machinery. This includes metrics such as temperature, vibration, pressure, and performance levels. The software continuously monitors these parameters, ensuring equipment health is tracked at all times.

2. Data Analysis and Fault Detection

Machine learning algorithms analyze the collected data to detect anomalies or deviations from normal operating conditions. By identifying unusual patterns, the software can predict potential failures and alert maintenance teams in advance. This helps to avoid sudden breakdowns and schedule maintenance during non-productive periods.

3. Automated Maintenance Scheduling

Instead of relying on fixed schedules or responding to equipment failures, predictive maintenance software generates automated maintenance schedules based on data-driven insights. This ensures that equipment is only serviced when necessary, optimizing resource allocation and reducing unnecessary maintenance costs.

4. Performance Optimization

Predictive maintenance doesn’t just focus on preventing failures; it also provides insights into how to optimize equipment performance. By understanding when equipment is operating at its peak efficiency, businesses can fine-tune their operations to reduce energy consumption, improve output, and minimize waste.

5. Supply Chain and Inventory Management

Predictive maintenance also integrates with inventory management systems to ensure that necessary parts and supplies are available when maintenance is due. This reduces lead times and ensures that parts are not overstocked or understocked, streamlining operations.

Advantages and Benefits of Predictive Maintenance Software

The implementation of predictive maintenance software comes with several key benefits that help businesses maximize productivity and reduce operational costs.

1. Reduced Downtime

Unplanned downtime is one of the biggest challenges faced by businesses that rely on machinery. Predictive maintenance software can detect issues before they cause equipment failures, allowing companies to schedule repairs at convenient times. By minimizing unplanned downtime, businesses can keep their operations running smoothly.

2. Extended Equipment Lifespan

With regular maintenance based on actual equipment conditions rather than fixed schedules, machinery tends to last longer and operate more efficiently. Predictive maintenance ensures that equipment is serviced only when necessary, preventing unnecessary wear and tear and extending its useful life.

3. Cost Savings

By preventing unexpected breakdowns, businesses can avoid costly emergency repairs, replacement of parts, and downtime. Predictive maintenance also helps optimize resource allocation by scheduling maintenance only when needed, reducing the need for expensive overhauls.

4. Improved Safety

Preventing equipment failures can significantly enhance workplace safety. Predictive maintenance reduces the likelihood of critical equipment malfunctions that could lead to accidents or safety violations. This not only improves employee safety but also helps businesses maintain compliance with industry safety regulations.

5. Optimized Maintenance Costs

Predictive maintenance allows companies to perform maintenance only when it is truly needed, avoiding unnecessary costs associated with traditional time-based maintenance schedules. This results in optimized maintenance costs and reduced labor expenses.

6. Increased Productivity

By reducing downtime, optimizing equipment performance, and extending equipment lifespan, predictive maintenance directly contributes to higher productivity. Machines are available for use more often, production rates improve, and overall operational efficiency is enhanced.

Quantifying the Value Added by Predictive Maintenance

To truly understand the value of predictive maintenance software, let’s examine the potential savings it offers to companies in the UAE compared to current practices.

1. Reduction in Downtime Costs

In many industries, downtime can be extremely costly. For example, in the manufacturing sector, the cost of downtime can be as high as AED 20,000 per hour. With predictive maintenance software, businesses can reduce downtime by up to 30%. For a manufacturing company that experiences 500 hours of downtime per year, predictive maintenance could save up to AED 3,000,000 annually.

2. Maintenance Savings

Traditional time-based maintenance schedules often lead to over-servicing or under-servicing equipment. Predictive maintenance ensures that equipment is only serviced when necessary, leading to maintenance savings of around 10% to 20% annually. For a company that spends AED 1,000,000 on maintenance annually, predictive maintenance could save AED 100,000 to AED 200,000 per year.

3. Extended Equipment Life

By performing targeted maintenance, predictive maintenance can extend the life of critical equipment. For high-value assets, this can lead to significant savings. If a company operates machinery worth AED 10,000,000, extending its life by 1 to 2 years could save an additional AED 500,000 to AED 1,000,000 in replacement costs.

4. Improved Energy Efficiency

Predictive maintenance also helps optimize energy usage by ensuring that equipment runs efficiently. For energy-intensive industries, reducing energy consumption by 10% can lead to savings of AED 200,000 to AED 300,000 annually, depending on the scale of operations.

5. Increased Productivity

With reduced downtime, optimized maintenance schedules, and improved equipment reliability, companies can increase productivity by up to 10% to 15%. This could result in an additional AED 500,000 to AED 1,000,000 in annual revenue for a mid-sized business.

Conclusion

Predictive maintenance software is a powerful tool that can help businesses optimize their operations, reduce costs, and improve safety and productivity. By leveraging AI and real-time data analytics, this software enables companies to forecast maintenance needs accurately, preventing costly equipment failures and extending the lifespan of critical assets.

For industries in the UAE, where operational efficiency and cost reduction are key priorities, predictive maintenance offers a unique opportunity to drive substantial savings and improve overall performance. Whether you’re in manufacturing, oil and gas, construction, or any other industry that relies on machinery, predictive maintenance software from Uniq Loop Technologies LLC can provide you with the tools you need to stay ahead of the competition and achieve long-term success.